Have you ever wondered why your windshield cracks in a spiderweb pattern while your side windows shatter into tiny pieces? This isn’t a manufacturing flaw—it’s brilliant engineering. Understanding the difference between laminated vs. tempered auto glass is crucial for every vehicle owner’s safety and financial decisions.

This guide will explore how these two types of safety glass protect you in different ways. We’ll break down the manufacturing processes, cost differences, and why proper installation matters more than ever with modern technology. You’ll learn exactly when repair is possible and when replacement becomes necessary for optimal protection.

What Is Safety Glass? A Brief Introduction

When we talk about auto glass, we’re not discussing the same material used in your home windows. Safety glass is specifically designed to minimize injury risk when broken. Both laminated and tempered varieties fall under this category, but they achieve safety through completely different methods. The fundamental difference lies in how they react to impact and what happens during failure.

This category was developed to address the dangers of standard annealed glass, which breaks into large, sharp shards. Whether you’re dealing with a windshield or side window, understanding that you’re protected by engineered safety glass provides peace of mind. The automotive industry uses these specific types because each is perfectly suited to its location’s unique safety requirements.

What Is Laminated Auto Glass? The Protective Windshield

Laminated auto glass serves as your vehicle’s primary defensive barrier. This sophisticated material consists of multiple layers designed to maintain integrity under extreme conditions. You’ll find it primarily in windshields because it provides crucial structural support and occupant protection that other glass types cannot match.

The development of laminated glass revolutionized automotive safety by addressing the major risks associated with windshield failure. Today’s versions incorporate advanced features beyond basic protection, including enhanced optical clarity and compatibility with modern sensor systems. Its unique properties make it indispensable for frontal collision protection.

How Laminated Glass Is Manufactured (The “Sandwich” Process)

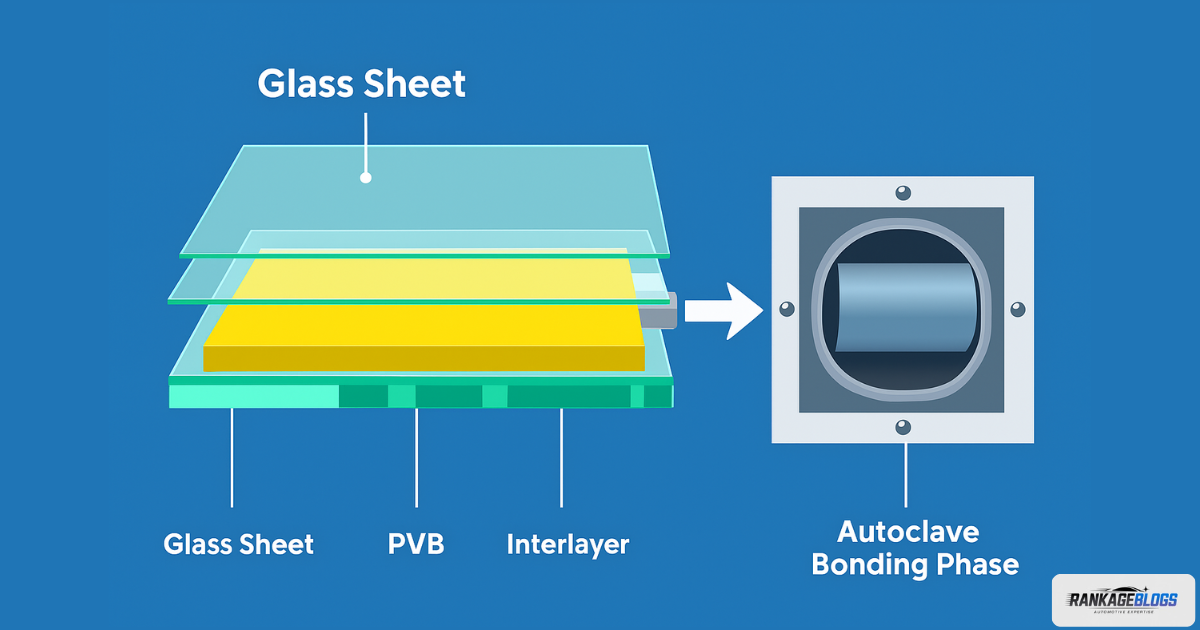

The manufacturing process for laminated glass creates what engineers call a “sandwich” structure. Here’s how it works:

1. Layer Preparation: Two sheets of glass are cut to the exact required shape and size for a specific vehicle model.

2. Interlayer Insertion: A thin, transparent layer of polyvinyl butyral (PVB) or adhesive resin interlayer is precisely placed between the glass sheets.

3. Bonding Phase: The stack undergoes a heating process (approximately 150-160°C) and pressing through rollers, which removes air pockets.

4. Autoclave Treatment: The assembly enters an autoclave (a high-pressure oven) where heat and pressure (around 200 psi) permanently bond the layers together.

This laminated glass construction creates a permanent bond that gives the glass its unique safety characteristics. The PVB interlayer is what keeps the glass from shattering apart upon impact, making it dramatically different from tempered glass in both composition and behavior.

The Key Purpose: Safety and Structural Integrity

The fundamental purpose of laminated glass is passenger ejection prevention during collisions. According to NHTSA data, proper windshield retention prevents approximately 80% of potential ejections in rollover crashes. The glass provides up to 60% of the structural support for your vehicle’s roof during a rollover accident.

This structural support is crucial because it maintains the survival space for occupants. The windshield safety features also include:

- Preventing the roof from collapsing completely during rollovers

- Creating a barrier that keeps occupants inside the vehicle

- Providing a mounting surface for rearview mirrors and electronic sensors

- Acting as a backstop for airbag deployment in many vehicle designs

These safety glass properties make laminated glass non-negotiable for windshield applications where rollover protection and occupant containment are primary concerns.

Common Applications: Where You’ll Find Laminated Glass

While windshields are the most common application, you’ll find laminated glass in other locations:

- All automotive windshields (mandated by DOT regulations)

- Moonroofs and sunroofs where overhead protection is needed

- Convertible rear windows where flexibility and clarity are required

- High-end luxury vehicle side windows for enhanced security and noise reduction

- Motorcycle windshields where rider protection is critical

The growing use of laminated glass in side windows particularly in luxury vehicle glass features demonstrates how manufacturers are increasingly prioritizing cabin quietness and security. Some European automakers now use laminated side glass as standard equipment for its superior sound insulation properties.

What Is Tempered Auto Glass? The Strategic Side Window

Tempered auto glass serves a different but equally important safety function in your vehicle. This type of glass undergoes a specialized strengthening process that makes it significantly more resistant to impact than standard glass. You’ll find it used throughout your vehicle wherever the safety priorities differ from those of the windshield.

The strategic use of tempered glass represents an important safety engineering decision. Manufacturers specifically choose this material for locations where emergency escape might be necessary or where different types of protection are prioritized. Understanding why manufacturers use tempered glass in specific locations helps you appreciate your vehicle’s overall safety system.

The Tempering Process: Heat, Chemicals, and Strength

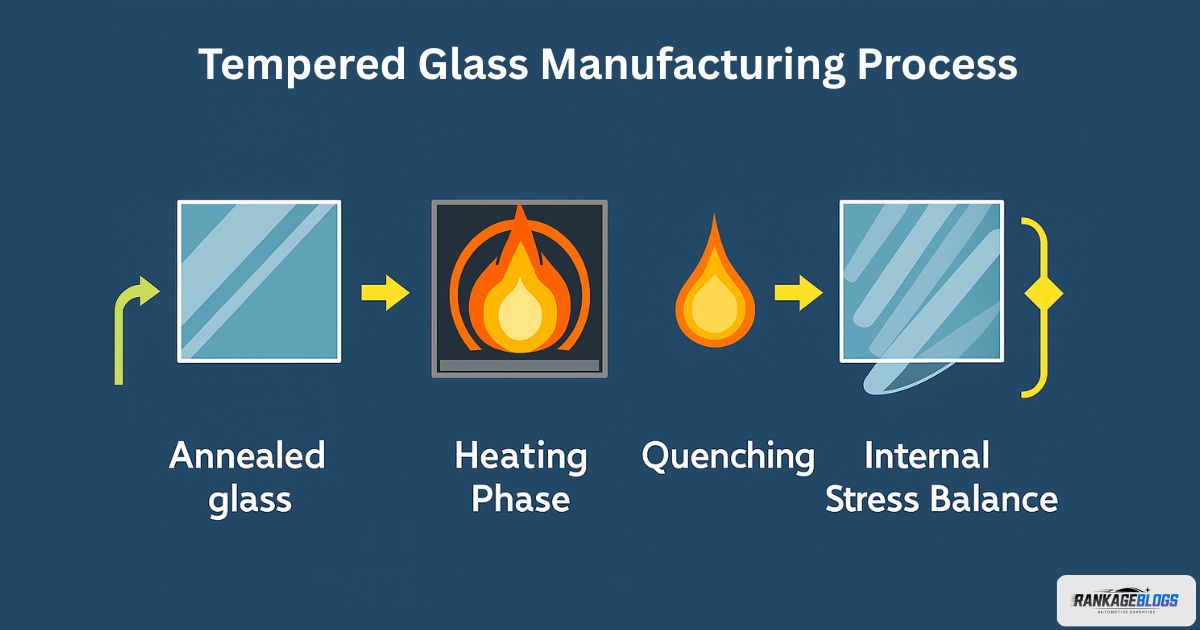

The tempered glass manufacturing process creates its unique strength through controlled thermal treatment:

- Preparation: Standard annealed glass is cut to its final dimensions before tempering begins.

- Heating Phase: The glass travels through a furnace where it’s heated to approximately 620-650°C (1150-1200°F), becoming slightly softened.

- Quenching Process: High-pressure air blasts cool the surface rapidly while the interior remains hot, creating surface compression and interior tension.

- Stress Equilibrium: This differential cooling creates balanced internal stresses that give tempered glass its characteristic strength.

This manufacturing process creates glass that is 4-5 times stronger than untreated glass of the same thickness. The heating and cooling process must be precisely controlled to achieve the perfect tensile strength and impact resistance that makes tempered glass ideal for side window applications.

The Key Purpose: Safe Breakage for Emergency Escape

The primary safety function of tempered glass is controlled failure. Unlike laminated glass that holds together, tempered glass is designed to disintegrate into small, relatively harmless pieces when broken. This break pattern serves several important safety functions:

- Emergency Egress: In submerged vehicle situations, tempered glass can be broken quickly for escape

- Rescue Access: First responders can easily breach windows to access occupants

- Injury Reduction: The small, dull fragments minimize cutting risk compared to sharp shards

- Post-Collision Safety: Broken windows won’t leave dangerous glass projections

This safe breakage design is particularly important for side windows because statistics show that rapid exit from a vehicle can be critical in certain accident scenarios, particularly submersion or fire situations where seconds matter.

Common Applications: Where You’ll Find Tempered Glass

Tempered glass appears throughout your vehicle in these key locations:

- Side windows (both front and rear door glass)

- Rear windows (backlights) in most vehicles

- Quarter windows and vent windows

- Convertible side windows where flexibility isn’t required

The applications are carefully chosen based on the specific safety requirements of each location. In side positions, the priority shifts from structural support (the windshield’s job) to emergency escape and occupant protection from flying glass during side impacts.

Laminated vs. Tempered Glass: A Direct Comparison

When comparing laminated vs. tempered auto glass, it’s essential to understand they’re engineered for different primary safety functions. This comparison will help you understand why manufacturers use each type in specific locations and why you shouldn’t interchange them. The choice between them involves multiple factors beyond just cost or appearance.

This direct comparison reveals how each type excels in its intended application while having limitations in other areas. We’ll examine the key differentiators that matter most for vehicle owners making repair or replacement decisions. Understanding these differences helps you make informed choices about maintenance and repairs.

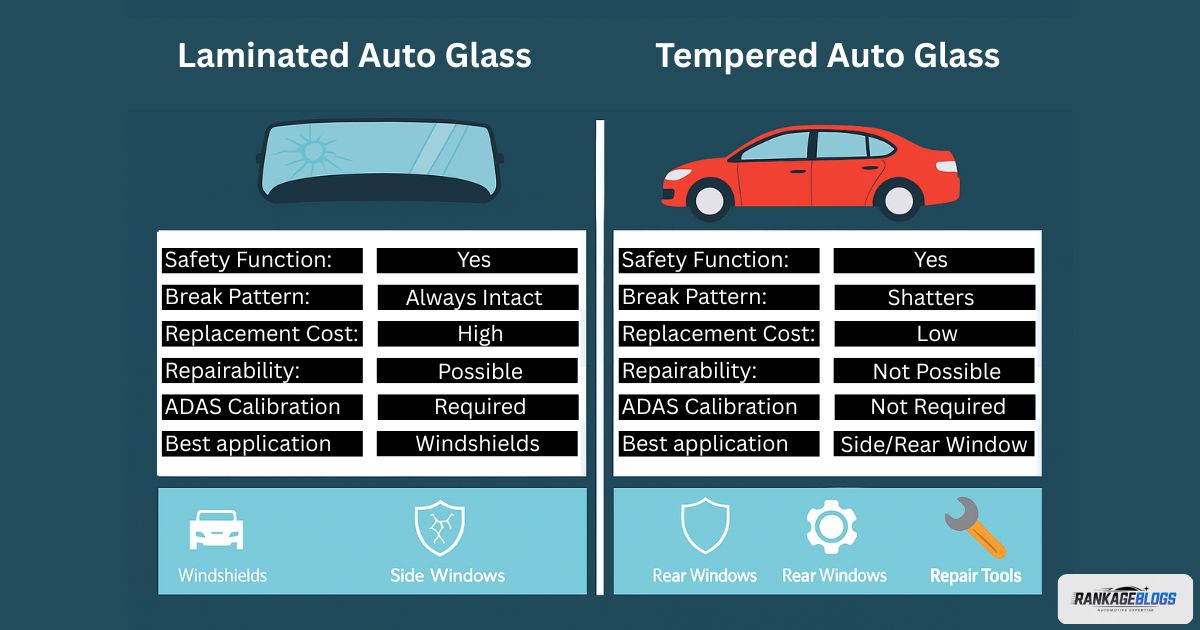

Here’s a quick overview of the key differences:

| Feature | Laminated Auto Glass (Windshields) | Tempered Auto Glass (Side/Rear Windows) |

| Primary Safety Function | Prevents ejection; provides structural support in rollovers. | Allows for safe emergency escape; minimizes injury from sharp edges. |

| Break Pattern | “Spider web” cracking; held together by the PVB interlayer. | Shatters into small, blunt, cube-like fragments. |

| Typical Replacement Cost | $250 – $600+ (Standard vehicle) $1,000+ (Luxury vehicle with ADAS calibration) | $100 – $400+ (Side window) |

| Repairable? | Yes, small chips and cracks can often be repaired. | No, any damage requires full replacement. |

| ADAS Calibration Required? | Yes, frequently (cameras/sensors are mounted behind it). | No, not typically required. |

| Best For | Windshields, sunroofs, security, noise reduction. | Side windows, rear windows |

1. Manufacturing Process: Layer Bonding vs. Heat Treatment

The fundamental difference begins at the production level with completely different manufacturing approaches:

Laminated Glass Manufacturing:

- Uses a sandwich construction with glass-PVB-glass layers

- Involves heat and pressure application in an autoclave

- Creates a composite material with combined properties

- Allows for curvature and complex shapes during formation

- Process takes longer and involves more materials

Tempered Glass Manufacturing:

- Uses a single piece of glass strengthened throughout

- Relies on rapid heating and cooling to create surface tension

- Cannot be cut or modified after the tempering process

- Must be shaped and cut before the final tempering stage

- Generally faster to produce than laminated glass

This difference in manufacturing process explains why laminated glass typically costs more to produce and replace. The laminated glass construction involves more materials and complex bonding processes, while tempered glass manufacturing is essentially a enhancement of single-piece glass.

2. Strength and Impact Resistance: Which Is Stronger?

The question of which glass is “stronger” depends on how you define strength:

Impact Resistance:

- Tempered glass has higher surface compression, making it more resistant to direct impacts from small objects

- Laminated glass has better resistance to penetration but may show surface damage more easily

Overall Durability:

- Tempered glass wins in surface hardness and scratch resistance

- Laminated glass provides better overall structural support to the vehicle frame

Stress Resistance:

- Tempered glass handles thermal stress better due to its balanced internal tensions

- Laminated glass has better flexibility and can withstand more bending before failure

In terms of glass durability comparison, tempered glass generally has better impact resistance to direct blows, while laminated glass’s ability to maintain integrity under stress is what provides the crucial structural support needed for windshields.

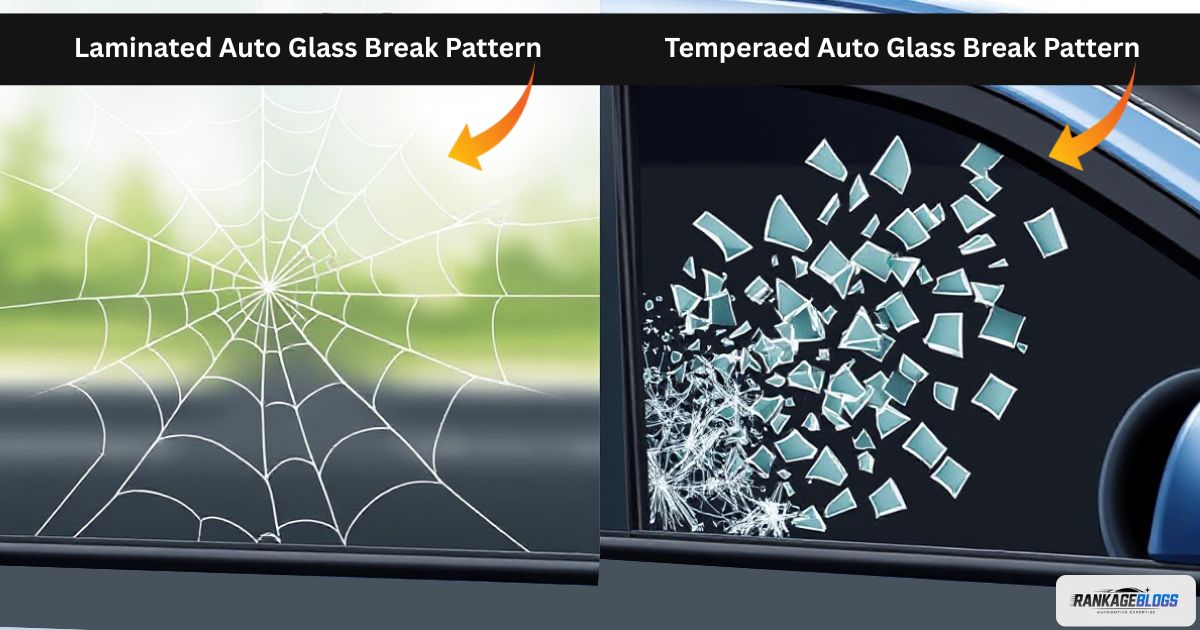

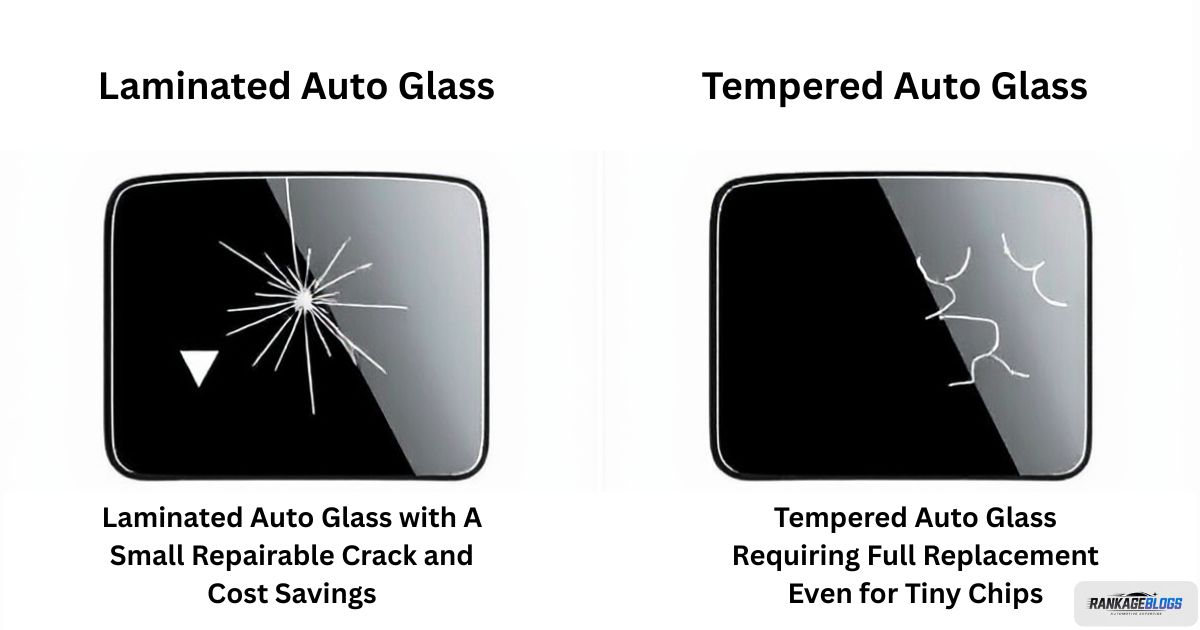

3. Safety Break Patterns: “Spider Web” vs. “Small Cubes”

The most visible difference between the two glass types is how they break:

Laminated Glass Break Pattern:

- Develops a “spider web” crack pattern when impacted

- The PVB interlayer holds broken pieces in place

- Maintains visibility and structural integrity even when cracked

- Can often be driven safely (at reduced speed) to a repair facility

- Creates no loose glass fragments inside the vehicle

Tempered Glass Break Pattern:

- Disintegrates completely into small, cube-like fragments

- The entire window typically collapses into harmless pieces

- Provides no barrier function once broken

- Creates a mess of small glass pieces but minimal injury risk

- Cannot be driven with a broken window due to weather elements

This difference in breakage pattern directly relates to each type’s safety function. Laminated glass maintains a protective barrier, while tempered glass eliminates sharp edges for safe emergency exit.

4. Applications: Windshields vs. Side and Rear Windows

The application differences are mandated by safety regulations and practical considerations:

Laminated Glass Applications:

- Windshields (required by federal law)

- Sunroofs and moonroofs

- High-security vehicles (all windows)

- Luxury vehicles (for noise reduction)

- Convertible rear windows

Tempered Glass Applications:

- Side windows (front and rear doors)

- Rear windows (in most vehicles)

- Quarter windows and small fixed glass

- Economy vehicle backlights

These applications are determined by the specific safety requirements of each location. The windshield requires the barrier protection of laminated glass, while side windows need the emergency egress capabilities of tempered glass.

5. Cost Differences: Manufacturing and Replacement

The cost difference between the two types is significant and consistent:

Laminated Glass Costs:

- Typically $250-$600 for windshield replacement

- Higher material costs due to multiple layers

- Complex installation requiring special tools and adhesives

- Often requires ADAS calibration adding $100-$400+ to cost

- Insurance coverage is more common (comprehensive usually covers)

Tempered Glass Costs:

- Typically $100-$400+ for side window replacement

- Simpler installation process in most cases

- No calibration requirements

- Less frequently covered by insurance without specific glass coverage

- Faster replacement time (often under one hour)

The cost differences reflect the more complex manufacturing process of laminated glass and the additional safety requirements of its primary application as a windshield.

6. How Glass Type Affects Repairability

Repairability varies significantly between the two glass types:

Laminated Glass Repairability:

- Small chips and cracks can often be repaired

- Repair is possible when damage is smaller than a dollar bill

- Repair costs $50-$150 versus $250-$600 for replacement

- Must be repaired before dirt contaminates the crack

- Not all damage locations are repairable (especially near edges)

Tempered Glass Repairability:

- Cannot be repaired once broken or damaged

- Requires complete replacement for any damage

- Even small chips necessitate full window replacement

- This is due to the tension equilibrium that would be disrupted by repair attempts

Understanding this glass repair vs. replacement dynamic helps you make quick decisions when damage occurs. With laminated glass, acting quickly can save significant money, while tempered glass damage always means replacement.

The Modern Factor: How ADAS Changes Windshield Replacement

Advanced Driver-Assistance Systems (ADAS) have revolutionized windshield replacement in recent years. These safety systems rely on cameras and sensors typically mounted near or on the windshield, making glass replacement more complex than ever before. Understanding this technological advancement is crucial for modern vehicle owners.

The integration of ADAS means your windshield is no longer just a piece of glass—it’s part of your vehicle’s safety system. This development has significant implications for repair quality, cost, and safety. Proper installation now requires technical expertise beyond traditional glass replacement skills.

What is ADAS Calibration and Why Is It Crucial?

ADAS calibration is the process of precisely aligning the cameras and sensors after windshield replacement to ensure they function correctly. This process is crucial because:

- Safety System Dependency: Features like automatic emergency braking, lane keeping, and adaptive cruise control rely on accurate sensor data

- Precision Requirements: Cameras must be aligned within fractions of a degree to function properly

- Legal Implications: Improper calibration could create liability issues if systems fail to prevent an accident

- System Integration: Modern ADAS features work together, so one miscalibrated sensor affects multiple systems

This calibration process typically involves specialized targeting equipment and factory-level diagnostic tools. Technicians must follow specific procedures for each vehicle make and model to ensure perfect alignment of these sensitive safety systems.

The Cost and Importance of Professional Recalibration

The ADAS calibration process adds significant cost and complexity to windshield replacement:

- Cost Range: Calibration typically adds $100-$400+ to the total replacement cost

- Time Investment: The process can take 30-90 minutes depending on the vehicle

- Equipment Requirements: Requires specialized calibration tools most DIYers don’t possess

- Certification Needs: Technicians often need manufacturer-specific training

The importance of professional calibration cannot be overstated. A miscalibrated system might not provide warnings until it’s too late to prevent an accident. This makes choosing a qualified installer more important than ever for modern vehicles equipped with these safety features.

Key Benefits and Advantages

Both types of auto glass offer distinct advantages that make them ideal for their specific applications. Understanding these benefits helps you appreciate why manufacturers choose each type for different locations in your vehicle. Each type represents an engineering solution optimized for particular safety priorities and performance requirements.

The benefits extend beyond basic safety to include comfort, convenience, and long-term ownership considerations. We’ll explore the specific advantages of each glass type to give you a complete picture of how they contribute to your overall driving experience and vehicle value.

Noise Reduction and UV Protection Benefits of Laminated Glass

Laminated glass provides significant benefits beyond basic safety:

Sound Insulation Properties:

- Reduces road and wind noise by up to 50% compared to tempered glass

- The PVB layer acts as a sound dampener, providing superior soundproofing against high-frequency noises

- Creates a noticeably quieter cabin environment, reducing driver fatigue

- Especially beneficial in luxury vehicles and during highway driving

UV Protection Capabilities:

- Blocks up to 99% of harmful ultraviolet radiation

- Protects interior materials from fading and deterioration

- Reduces skin cancer risk for occupants during extended driving

- Helps maintain cabin temperature by rejecting solar energy

These sound insulation and UV protection benefits make laminated glass particularly valuable in windshield applications where occupants spend the most time exposed to environmental elements. The laminated glass essentially acts as a sophisticated environmental barrier.

The Strength and Durability Advantages of Tempered Glass

Tempered glass offers unique advantages that make it ideal for side applications:

Surface Strength:

- 4-5 times stronger than annealed glass of equivalent thickness

- Superior resistance to scratches and minor impacts

- Better thermal shock resistance than laminated glass

- Maintains clarity and optical quality over time

Safety Performance:

- Provides reliable, predictable breakage pattern for emergency situations

- Eliminates dangerous sharp edges completely

- Lightweight compared to laminated alternatives

- Cost-effective for applications where multiple windows are needed

The strength and durability of tempered glass make it ideal for side windows where scratch resistance and reliable emergency breakage are prioritized over noise reduction and UV protection. The glass durability comparison clearly shows each type excels in its intended role.

Practical Guide for Car Owners

Making informed decisions about your auto glass requires understanding practical considerations beyond technical specifications. This section provides actionable guidance for common situations vehicle owners face. From insurance claims to repair decisions, having the right information helps you navigate auto glass issues confidently.

Your approach to auto glass maintenance and repair should balance safety, cost, and convenience factors. We’ll provide specific guidance on the most common questions and concerns vehicle owners have when dealing with glass damage or replacement needs.

Which Glass Type Is Better for Windshields vs. Side Windows?

The question of which glass is “better” depends entirely on the application:

For Windshields: Laminated Glass is Essential

- Provides structural support for the vehicle roof

- Prevents passenger ejection during collisions

- Allows for rock chip repairs in many cases

- Supports camera and sensor systems for ADAS features

- Required by federal safety regulations

For Side Windows: Tempered Glass is Ideal

- Provides safe emergency exit when needed

- Less expensive to replace when broken

- Lighter weight than laminated alternatives

- No calibration requirements after replacement

- Standard for side applications in all vehicles

The simple answer is that each type is better for its specific application. You should never substitute tempered glass for a windshield or laminated glass for side windows unless specifically designed for that purpose by the manufacturer.

Insurance Coverage Differences for Each Type

Understanding insurance coverage helps you manage glass-related expenses:

Windshield (Laminated Glass) Coverage:

Laminated glass is typically covered under comprehensive insurance, with several important features:

- Often has zero deductible for repair, with a small deductible for replacement.

- Most insurers encourage repair over replacement when possible.

- ADAS calibration costs are typically included in claims.

- Claims usually don’t affect your premium rates.

Side Window (Tempered Glass) Coverage:

Tempered glass is also covered under comprehensive insurance, but with some key differences:

- Deductibles may be higher than for windshield claims.

- Repair isn’t possible, so all claims involve full replacement.

- Coverage terms vary more significantly between insurance providers.

- Some policies offer specific optional glass coverage for better protection.

Before filing a claim, check your specific policy details and consider the cost relative to your deductible. Many insurers have preferred repair networks that can simplify the process and potentially save you out-of-pocket expenses.

Choosing the Right Glass for Your Vehicle

When replacement becomes necessary, consider these factors:

OEM vs. Aftermarket Glass:

- OEM (Original Equipment Manufacturer) glass matches factory specifications exactly

- Aftermarket glass may vary in quality and fitment

- ADAS systems may require OEM glass for proper calibration

- Insurance companies may specify which type they’ll cover

Installation Quality Considerations:

- Choose installers certified by major glass manufacturers

- Verify they have proper calibration equipment for ADAS vehicles

- Check reviews and reputation before selecting an installer

- Ensure proper adhesives and installation procedures are followed

Safety Verification:

- Test all functions after installation (defrosters, sensors, etc.)

- Verify proper wind and water sealing after installation

- Check for optical distortions that could affect driving

- Understand the cure time before driving in rainy conditions

Making the right choice ensures your new glass provides the same safety and performance as the original equipment. Don’t compromise on quality, especially for windshield replacements where safety implications are significant.

Conclusion

Ultimately, the choice between laminated and tempered auto glass isn’t one you need to make—your vehicle’s engineers already have. Laminated glass serves as a protective shield for your windshield, designed to keep you safe by holding together during an impact.

Tempered glass acts as a strategic escape hatch in your side windows, shattering safely to allow for emergency exit. Both are masterpieces of safety engineering, each excelling in its specific role. Understanding their differences empowers you to make informed decisions about repairs, insurance, and the critical importance of professional installation, especially for modern ADAS-equipped vehicles. Your safety on the road relies on this precise combination.

Frequently Asked Questions (FAQs)

What is the difference between laminate glass and tempered glass?

Laminated glass is a sandwich of glass and plastic that cracks but holds together, while tempered glass is a single, heat-treated pane that shatters into harmless cubes.

Is tempered glass stronger than laminated glass?

Tempered glass has higher surface strength against impacts, but laminated glass provides greater overall structural integrity and remains intact after breaking.

Is tempered glass better than laminated glass in cars?

Neither is universally better; laminated is essential for windshields for safety, while tempered is ideal for side windows for emergency escape.

What’s more expensive, laminated or tempered glass?

Laminated glass is more expensive due to its complex multi-layer manufacturing process.

Laminated vs tempered auto glass price?

Laminated (windshield) replacement typically costs $250-$600+ (Standard vehicle) and $1,000+ (Luxury vehicle with ADAS calibration), while tempered (side window) replacement is usually $100-$400+.

Tempered glass vs laminated glass price?

Tempered glass is generally less expensive than laminated glass for automotive applications.

Laminated tempered glass price?

This combination glass (laminated tempered) is a premium product used in high-security or hurricane-resistant applications and is significantly more expensive than standard types.

Why is windshield replacement more expensive?

Windshield replacement costs more due to the price of laminated glass, specialized installation, and often required ADAS camera recalibration.

Can a windshield be made of tempered glass?

No, it is illegal and extremely unsafe; windshields must be laminated to prevent ejection and provide structural support.

How do I know if my car has tempered or laminated glass?

Your windshield is always laminated; side and rear windows are almost always tempered (look for a “TEMPERED” etching in the corner).

Does Toyota use tempered or laminated glass?

Toyota, like all manufacturers, uses laminated glass for windshields and tempered glass for side and rear windows, adhering to global safety standards.

What are the disadvantages of using laminated glass in cars?

The main disadvantages are higher cost, greater weight, and the potential for optical distortion compared to tempered glass.

Can laminated auto glass be repaired?

Yes, small chips and cracks in laminated windshields can often be professionally repaired, which is cheaper than replacement.

Laminated glass vs tempered glass strength?

Tempered glass is harder to break initially, but laminated glass is stronger in maintaining structural support after impact.

What is laminated tempered glass?

It is a high-security glass made by laminating two sheets of already-tempered glass, combining the safety features of both types.

Safety glass vs tempered glass?

“Safety glass” is the category that includes both tempered and laminated glass; tempered is one specific type of safety glass.

What is ADAS calibration?

It is the process of realigning cameras and sensors on a windshield after replacement to ensure advanced driver-assistance systems function correctly.

Laminated vs tempered glass skylight?

Laminated glass is better for overhead skylights as it provides a safe barrier if broken, while tempered is prone to falling out entirely upon breakage.