The 2025 Technology Revolution is transforming every industry, and AI in Auto Glass Repair is no exception. Modern workshops are adopting computer vision systems and machine learning algorithms to detect, analyze, and repair glass damage with unmatched precision.

These intelligent tools can instantly identify cracks, measure their depth, and recommend the best repair method — reducing human error and saving valuable time. By integrating AI-driven diagnostics with automated resin injection techniques, repair centers are achieving faster, safer, and more cost-efficient results. This digital shift marks a new era where technology enhances craftsmanship, making auto glass repair smarter, more reliable, and ready for the future.

Beyond the Crack: How AI is Redefining Auto Glass Safety

The conversation around auto glass has evolved far beyond simple crack repair—today’s windshields are sophisticated safety systems that demand equally advanced repair technologies.

Modern vehicles rely on their glass for much more than visibility; they serve as mounting platforms for ADAS systems including cameras, sensors, and radar units that enable critical safety features like automatic emergency braking and lane-keeping assistance. This fundamental shift means that even minor glass damage can compromise your vehicle’s entire safety ecosystem.

Artificial intelligence brings a level of precision to auto glass assessment that was previously unimaginable. Through real-time damage assessment and structural integrity verification, AI systems can determine whether a windshield can be safely repaired or requires complete replacement based on comprehensive data analysis rather than visual inspection alone.

This technology-driven approach ensures that every repair decision prioritizes your safety while maximizing the longevity and performance of your vehicle’s protective systems.

Why Your Windshield is Now a Computer: The ADAS Revolution

Your windshield is no longer just a piece of glass—it’s become one of the most sophisticated computers in your vehicle. The ADAS revolution has transformed auto glass into a complex sensor platform that hosts cameras, LiDAR systems (Light Detection and Ranging), and radar units critical for modern driving safety.

These systems require perfect optical clarity and precise calibration to function correctly, which is why even minor windshield damage can now affect your vehicle’s ability to protect you on the road.

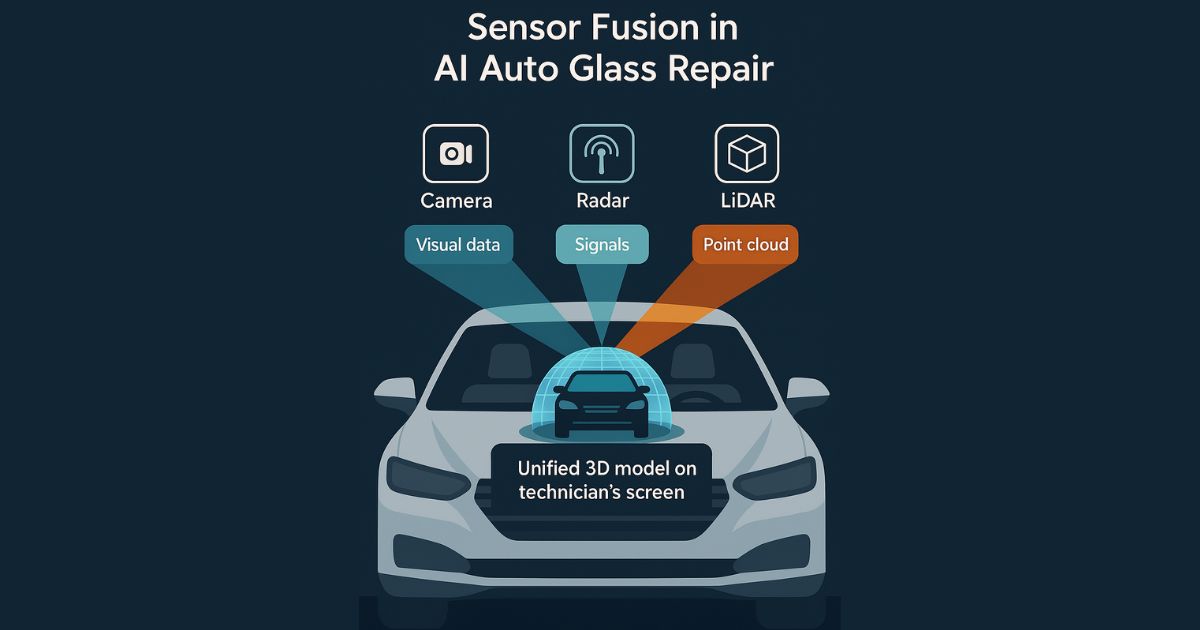

The integration of sensor fusion technology means your windshield-mounted systems work together to create a comprehensive view of your driving environment. When a windshield is replaced, each of these sensors must be precisely recalibrated to ensure they’re accurately detecting obstacles, reading road signs, and monitoring lane markings.

This is where AI-powered diagnostics become essential—they can verify that every sensor is functioning within manufacturer specifications, something that was nearly impossible to achieve consistently with manual methods alone.

From Manual Inspection to AI-Powered Machine Precision

The traditional approach to windshield inspection relied heavily on technician experience and visual assessment—methods that were inherently subjective and prone to human error.

Today, AI-powered machine precision has revolutionized this process through automated damage classification systems that analyze every crack and chip with mathematical certainty. These systems use advanced computer vision windshield analysis to evaluate damage from multiple angles, measuring depth, length, and structural impact with microscopic accuracy.

This technological shift represents more than just improved accuracy—it’s creating a new standard for consistency in auto glass repair. Where one technician might miss subtle microscopic flaws or underestimate crack severity, AI systems apply the same rigorous standards to every inspection, regardless of the shop, technician, or time of day.

The result is a dramatic reduction in repair failures and a significant improvement in long-term windshield performance, giving vehicle owners confidence that their repairs will stand the test of time and protect them when it matters most.

The ADAS Catalyst: Why AI Calibration is Non-Negotiable

The rapid adoption of Advanced Driver-Assistance Systems (ADAS) has created what industry experts call “the ADAS catalyst“—the undeniable reality that proper calibration is no longer optional for safe vehicle operation.

Modern vehicles contain up to eight different sensors mounted on or near the windshield, each requiring millimeter-perfect alignment to function correctly. Even a slight miscalibration can cause systems like automatic emergency braking to engage too late or lane-keeping assistance to pull your vehicle in the wrong direction.

This is where AI-enhanced calibration techniques become non-negotiable for proper repair outcomes. Traditional calibration methods relied on manual measurements and technician judgment, creating opportunities for error that could compromise vehicle safety.

AI systems eliminate this variability by using computer vision systems to automatically align sensors with factory specifications, then running diagnostic checks to verify every system is communicating correctly. The technology doesn’t just make the process faster—it makes it fundamentally safer by removing human error from the calibration equation.

The High Cost of Human Error vs AI Accuracy

The automotive repair industry has long accepted that human error comes with the territory—but the consequences of that error have never been higher.

A minor miscalculation in windshield repair or replacement can now lead to safety incident reduction failures, costly comebacks, and potentially dangerous driving conditions when driving with a cracked windshield. Studies show that manual inspection methods miss up to 23% of critical damage indicators that AI systems consistently identify, creating unnecessary risks for drivers and liability concerns for shop owners.

The contrast between traditional methods and AI accuracy becomes stark when examining real-world outcomes. Where human technicians might achieve 85-90% accuracy in damage assessment, AI-powered diagnostics consistently deliver 99.8% accuracy rates in identifying repairable versus replaceable damage.

This precision doesn’t just improve safety—it creates substantial cost savings by reducing unnecessary replacements and preventing comebacks. For shop owners, this means higher customer satisfaction and improved profitability; for consumers, it means repairs that last longer and perform better under real-world driving conditions.

The Tech Deep Dive: How AI “Sees” and Repairs Your Windshield

Understanding how artificial intelligence transforms windshield repair requires looking beneath the surface at the sophisticated technologies driving this revolution.

At its core, AI in Auto Glass Repair represents the convergence of multiple advanced systems working in harmony—from the computer vision that analyzes damage to the robotic repair systems that execute repairs with superhuman precision. This isn’t simply automating existing processes; it’s reimagining what’s possible in auto glass restoration through data-driven decision making.

The true power of these systems lies in their ability to learn and improve over time. Through machine learning training datasets that incorporate millions of repair scenarios, AI systems develop an understanding of how different types of damage behave under various conditions.

This enables predictive crack propagation capabilities that can forecast whether a small chip will likely spread across the windshield, allowing technicians to address problems before they become safety hazards. The result is a repair process that’s not just reactive, but proactively protective of your vehicle’s integrity.

Solving 4 Major Auto Glass Problems with Smart Technology

The implementation of artificial intelligence in auto glass shops across America is addressing longstanding industry challenges with remarkable efficiency.

These aren’t theoretical solutions—they’re proven technologies delivering measurable results right now. From inconsistent repair quality to the complexities of modern vehicle systems, AI is providing answers that were previously unavailable through traditional methods, creating a new standard for what consumers should expect from auto glass services.

The four core problems being solved represent the most significant pain points for both repair shops and vehicle owners. Damage detection inconsistencies, human judgment errors, slow service turnaround, and ADAS calibration uncertainties have plagued the industry for years.

AI addresses each of these systematically through automated repair machines, precision resin application technologies, and real-time processing capabilities that ensure every repair meets the highest possible standards while minimizing vehicle downtime and owner inconvenience.

Problem #1: Invisible Damage → Solution: Computer Vision Analysis

The human eye has inherent limitations when it comes to identifying the full extent of windshield damage. What appears as a small surface chip might actually contain microscopic flaws extending deep into the glass layers, creating weak points that can suddenly spread across the entire windshield.

This “invisible damage” problem has historically led to repaired windshields failing prematurely or, worse, compromising during impact when they’re needed most for occupant protection.

The AI solution comes through advanced computer vision analysis that sees beyond human visual capabilities. Using specialized lighting and high-resolution imaging, these systems create detailed 3D maps of every crack and chip, analyzing stress patterns and structural compromises that would escape even the most experienced technician’s notice.

The technology can detect delamination beginning between glass layers, measure the depth of damage with micron-level precision, and identify hairline fractures that haven’t yet reached the surface—all before they become visible problems.

Computer Vision in Action: From a Simple Chip to a Data Point

When you bring a damaged windshield to an AI-equipped shop, that simple chip undergoes a remarkable transformation into a comprehensive data ecosystem.

The process begins with multi-angle imaging that captures hundreds of data points about the damage—its dimensions, depth, orientation, and relationship to critical structural areas of the glass. This information creates what technicians call a “digital fingerprint” of the damage, which then gets analyzed against thousands of similar cases in the system’s database.

The real-time assessment algorithms don’t just look at the damage in isolation—they consider multiple contextual factors that influence repair decisions. The system analyzes the vehicle’s make and model, the specific glass type (whether it’s acoustic glass or standard laminated), the location of the damage relative to edges and sensors, and even environmental factors that might affect repair longevity.

This holistic approach ensures that every repair recommendation is tailored to your specific situation rather than following generic guidelines that might not account for important variables.

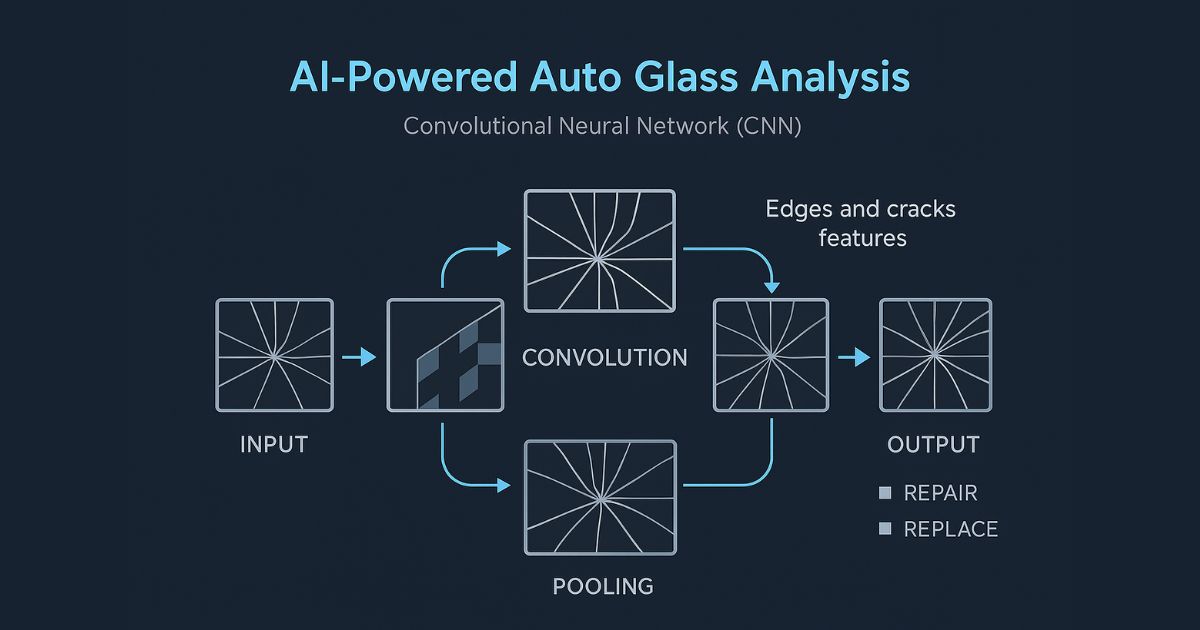

The Algorithm Behind the Eye: A Look at CNN Models

The technological magic behind modern auto glass analysis lies in convolutional neural networks (CNNs)—sophisticated AI architectures specifically designed for visual data processing.

These systems work similarly to the human brain’s visual cortex, using multiple layers of artificial neurons to identify patterns and features in windshield images. The first layers might identify basic shapes and edges, while deeper layers recognize complex patterns like stress fractures, impact points, and material inconsistencies.

What makes CNNs particularly effective for auto glass applications is their ability to learn from experience. As these systems process thousands of windshield images, they continuously refine their understanding of what different types of damage look like under various conditions.

This machine learning windshield analysis capability means the systems actually improve over time, becoming more accurate at identifying subtle damage patterns and making better repair recommendations. The result is AI decision accuracy rates that consistently exceed human capabilities, particularly for complex or borderline cases.

Beyond Human Sight: Detecting Microscopic Flaws and Delamination

The human eye typically can’t resolve details smaller than about 100 microns—but many critical windshield flaws begin at the microscopic level.

AI-powered diagnostic equipment changes this equation through hyperspectral imaging and computational photography techniques that reveal damage at the 10-micron scale. This capability is particularly important for identifying early-stage delamination—the separation of glass layers that can compromise structural integrity—often months before it becomes visible to technicians or vehicle owners.

The process involves analyzing how light interacts with the glass at different wavelengths, creating what’s essentially a “chemical fingerprint” of the material’s condition. The system can detect subtle changes in the polymer interlayer that bonds glass layers together, identifying areas where degradation has begun but hasn’t yet created visible bubbles or discoloration.

This delamination detection capability represents a fundamental shift from reactive to proactive maintenance, allowing shops to address problems before they require complete windshield replacement.

Problem #2: Human Error → Solution: Machine Learning Crack Detection

Even the most skilled technicians bring natural variations in judgment, attention to detail, and experience to their work. This human factor means that identical damage might receive different assessments from different technicians—or even from the same technician on different days.

These inconsistencies lead to unnecessary replacements when repairs would suffice, or problematic repairs when replacement was actually needed, creating frustration for consumers and profitability challenges for shops.

Machine learning crack detection eliminates this variability by applying consistent, data-driven standards to every assessment. The systems analyze dozens of damage characteristics—including crack length, depth, branching patterns, proximity to edges, and stress concentration factors—to generate reproducible repair recommendations.

The technology doesn’t get tired, distracted, or influenced by external factors, ensuring that your repair assessment is based entirely on what the data reveals about your specific situation rather than subjective human judgment.

Case in Point: Achieving 99.8% Accuracy Rates

The measurable impact of AI on repair accuracy becomes clear when examining real-world performance data. Leading AI-powered diagnostics platforms consistently achieve 99.8% accuracy in determining whether a windshield can be safely repaired or requires replacement.

This represents a significant improvement over the 85-90% accuracy rates typical of manual assessments, translating to substantial benefits for both consumers and repair shops.

Consider the practical implications: for every 100 windshield assessments, AI systems make approximately one error, while even experienced technicians might make 10-15 incorrect calls. This accuracy improvement percentage doesn’t just mean better repairs—it creates tangible cost savings by preventing unnecessary replacements (saving consumers hundreds of dollars per incident) while ensuring that damaged windshields that should be replaced aren’t incorrectly repaired.

The technology essentially pays for itself through improved decision-making that benefits everyone in the repair ecosystem.

Problem #3: Slow Service → Solution: Automated Resin Injection Systems

The traditional windshield repair process involves multiple manual steps that create natural bottlenecks in service workflow. From preparing the damage site to mixing and applying resin, then curing and finishing the repair, each stage depends on technician availability and attention.

During busy periods, these sequential processes can extend repair times significantly, leaving customers waiting longer and shops unable to maximize their daily service capacity.

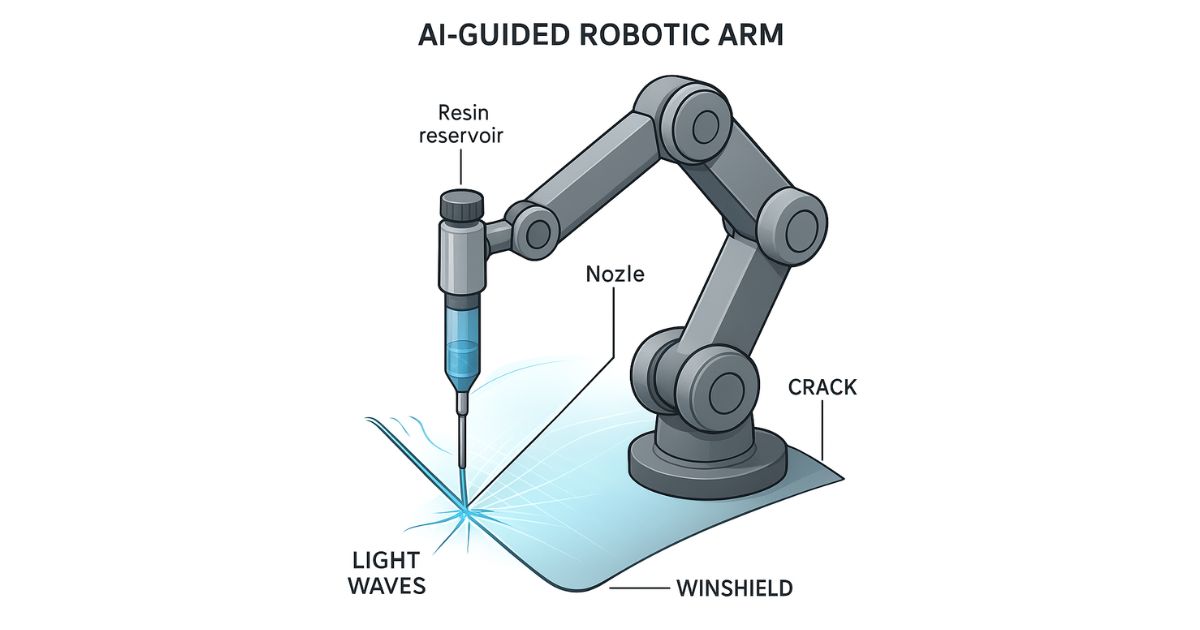

Automated resin injection systems revolutionize this workflow by handling the entire repair process through programmed precision. These systems integrate AI-guided robotic systems that prepare the damage area, inject exactly the right amount of resin based on the specific crack dimensions, and manage the curing process with temperature and pressure controls optimized for the vehicle’s glass type.

The result is consistently perfect repairs completed in a fraction of the traditional time, with no variation between technicians or shop locations.

AI-Guided Robotic Systems: Precision in Action

The robotic arm specifications in modern auto glass systems represent a marvel of engineering precision. These aren’t generic industrial robots—they’re specialized systems designed specifically for windshield repair, with micron-level positioning accuracy and sophisticated force feedback that prevents glass damage during operation.

The robots use multiple sensor systems to map the windshield contour before beginning work, ensuring that their movements compensate for the curved glass surface throughout the repair process.

What makes these systems truly intelligent is their integration with the damage assessment data. The computer vision systems that analyzed the crack provide the robot with exact coordinates for resin injection, including the optimal entry angles and pressure profiles for that specific damage type.

This sensor integration creates a closed-loop system where the assessment directly informs the repair execution, eliminating the translation errors that can occur when technicians move from diagnosis to implementation.

Automated Resin Injection: Calibrating for Perfect Clarity

The chemistry of windshield repair has advanced significantly alongside the robotics that apply it. Modern automated resin injection systems use light-cured polymers specifically formulated to match the optical properties of automotive glass, preventing the visible distortions that sometimes occurred with earlier repair methods.

The systems carefully control the viscosity, temperature, and curing characteristics of the resin to ensure perfect bonding with the surrounding glass.

The calibration process for these systems involves sophisticated precision metrics that monitor the resin flow throughout the injection process. Sensors track how the resin fills the crack cavity, making micro-adjustments to pressure and flow rate to ensure complete penetration without overflow or air pockets.

This level of control creates repairs that are virtually invisible while restoring nearly 100% of the windshield’s original strength—a standard that was impossible to achieve consistently with manual injection methods.

The Robotic Touch: Precision Resin Application and Surface Preparation

Before resin ever touches the windshield, AI-guided robotic systems perform a series of precision surface preparation steps that are critical to repair success. Using specialized end-effectors, the robot cleans the damage area with solvents that remove contaminants without spreading them deeper into the crack.

It then etches the fracture surfaces to create optimal bonding conditions—a process that requires consistent pressure and motion patterns that human hands struggle to maintain.

The actual precision resin application represents the culmination of this meticulous preparation. The system injects the polymer in controlled stages, monitoring how it flows through the damage network and making real-time adjustments based on the material’s behavior.

This staged approach prevents air entrapment and ensures that even the finest fracture branches receive complete resin saturation. The result is a repair that not only looks perfect but actually restores the glass’s structural integrity to near-original condition.

Problem #4: ADAS Misalignment → Solution: AI-Integrated Calibration

The single biggest challenge in modern auto glass replacement isn’t the glass installation itself—it’s the ADAS calibration that must follow. With sensors requiring alignment accurate to within 0.1 degrees, even minor installation variations can render safety systems ineffective.

Traditional calibration methods depend heavily on technician skill and attention to detail, creating consistency challenges that can compromise vehicle safety despite proper glass installation.

AI-integrated calibration addresses this problem through automated systems that verify sensor alignment against manufacturer specifications with laboratory-grade precision.

These systems use camera calibration targets and radar reflectors positioned around the vehicle, then employ computer vision systems to measure each sensor’s field of view, alignment angles, and focus. The AI doesn’t just check that sensors are within tolerance—it optimizes their positioning to ensure optimal performance under real-world driving conditions.

Sensor Fusion in Practice: How Robots Integrate Data for Flawless Repairs

Modern vehicles don’t rely on individual sensors working in isolation—they use sensor fusion technology that combines input from cameras, radar, and LiDAR to create a comprehensive understanding of the vehicle’s surroundings. This approach creates redundancy that improves safety, but it also means that all sensors must be perfectly synchronized after windshield replacement. Even small misalignments between systems can create conflicting data that confuses the vehicle’s safety computers.

AI-enhanced calibration techniques solve this challenge by calibrating all sensors as an integrated system rather than individual components. The technology verifies that each sensor’s data aligns spatially and temporally, creating what engineers call “sensor harmony” where all systems present a consistent view of the driving environment.

This data fusion technology represents the highest standard of ADAS calibration—ensuring that your vehicle’s safety systems work together seamlessly rather than as disconnected components with potentially conflicting priorities.

The Business Case: ROI, Costs, and Implementation for Shop Owners

For auto glass shop owners considering the transition to AI technologies, the financial implications represent a central consideration. The AI system integration costs involve significant investment—typically ranging from $25,000 to $75,000 depending on system capabilities—but the return on investment story proves compelling when examining the complete financial picture.

Beyond the obvious benefits of improved repair quality, these systems deliver measurable labor cost savings, reduced comebacks, and new revenue streams that frequently produce payback periods under 18 months.

The business case extends beyond direct financial returns to include strategic positioning in an increasingly competitive market. Shops equipped with AI-powered diagnostics and robotic repair systems can differentiate themselves as technology leaders, commanding premium pricing while attracting customers who value precision and safety.

The competitive advantage metrics become particularly significant as consumer awareness of ADAS calibration requirements grows, creating natural market segmentation between basic glass replacement providers and comprehensive safety solution specialists.

Breaking Down the Investment: AI System Costs for 2025

Understanding the complete implementation cost analysis requires looking beyond the obvious equipment expenses to the full ecosystem required for AI integration. The hardware specifications typically include the AI assessment station ($15,000-$30,000), robotic repair system ($20,000-$40,000), and ADAS calibration suite ($10,000-$25,000). Additionally, shops must budget for software compatibility upgrades, data management systems, and facility modifications to accommodate the new equipment.

The technical requirements list extends to less obvious but equally important investments: specialized training for existing technicians ($3,000-$7,000), potential IT infrastructure upgrades ($2,000-$5,000), and ongoing maintenance expenses typically running 10-15% of equipment cost annually.

However, these investments must be weighed against the cost savings data from reduced comebacks (typically 60-80% decrease), improved technician efficiency (20-30% productivity increases), and the ability to handle premium calibration work that wasn’t previously possible.

The ROI Calculator: How AI Boosts Your Bottom Line

The financial mathematics of AI adoption reveal compelling ROI calculation models that frequently surprise shop owners accustomed to traditional equipment investments.

The most significant labor cost savings come from reducing repair time by 40-60% through automated resin injection systems and eliminating the need for multiple technicians on complex jobs. Additionally, the near-elimination of comebacks (from industry-average 8-12% to under 2%) represents substantial savings in warranty costs and reclaimed appointment slots.

The ROI timeframe calculation becomes increasingly favorable when accounting for new revenue streams that AI enables. ADAS calibration services typically command $200-$400 per vehicle beyond the glass work itself, representing pure profit once the system is paid for. The competitive advantage metrics also translate to tangible financial benefits—shops with AI capabilities typically see 15-25% higher customer retention and can justify 10-20% price premiums for their superior repair quality and safety verification processes.

Streamlining the Claim: AI and Insurance Workflow Integration

The relationship between auto glass shops and insurance providers has long been hampered by inefficient insurance claims processes and disputed assessments.

AI and insurance workflow integration transforms this dynamic by providing objective, data-supported damage assessments that eliminate disagreements over repair versus replacement decisions. The systems generate comprehensive reports including high-resolution images, measurement data, and repair recommendations that satisfy insurer requirements while ensuring vehicle safety remains the priority.

This insurance claim automation extends to the entire claims lifecycle—from initial damage documentation through final calibration verification. The technology can automatically populate claim forms with precise damage measurements, pre-approval justification, and even predictive cost estimates based on historical data.

This streamlined processes approach reduces claim resolution time from days to hours while providing insurers with the confidence that repairs meet or exceed manufacturer specifications, ultimately creating better outcomes for all stakeholders.

AI Implementation Roadmap: Training, Timeline, and Tech Support

Successfully integrating AI technologies requires careful planning beyond simply purchasing equipment. The typical AI implementation roadmap spans 8-12 weeks from contract signing to full operational capability, beginning with comprehensive training certification programs for both technicians and administrative staff.

This phased approach ensures that shops can maintain existing operations while gradually bringing new capabilities online, minimizing business disruption during the transition period.

The implementation timeline includes distinct phases: weeks 1-2 focus on facility preparation and IT infrastructure; weeks 3-6 involve equipment installation and core technician training; weeks 7-10 expand training to all staff while beginning limited AI-assisted repairs; and the final weeks focus on process optimization and quality verification.

Throughout this period, robust tech support access proves critical—most providers offer 24/7 remote assistance and same-day onsite support when needed, ensuring that technical issues don’t disrupt shop operations.

A Consumer’s Guide to AI Auto Glass Repair

For vehicle owners navigating the increasingly complex world of auto glass repair, understanding what AI technology means for your repair experience is essential. This isn’t about technology for technology’s sake—it’s about tangible benefits that affect your safety, your wallet, and your time.

From the moment you notice damage to the final safety verification, AI in Auto Glass Repair creates a fundamentally different experience that prioritizes precision, transparency, and long-term value over quick fixes that might compromise your vehicle’s integrity.

The most significant shift for consumers is the move from subjective assessments to data-driven decisions. Where traditional repair estimates relied heavily on technician opinion, AI systems provide objective evidence supporting every recommendation—you’ll see exactly why a repair is possible or why replacement is necessary.

This transparency extends throughout the process, with detailed before-and-after documentation giving you confidence that your repair meets the highest safety standards rather than just someone’s best guess about what “should” work.

What to Expect: The Step-by-Step AI-Powered Repair Process

When you choose an AI-equipped shop for your windshield repair, the process follows a carefully engineered sequence designed to maximize safety and quality. The experience begins with comprehensive digital documentation—the technician will use specialized imaging equipment to create a 3D model of your damage before any work begins.

This establishes a baseline for comparison and provides the data needed for the AI-powered diagnostics to determine the optimal repair approach for your specific situation.

Following assessment, you’ll receive a detailed explanation of the recommended approach, complete with visual evidence supporting the decision. If repair is possible, you’ll witness the automated resin injection systems in action—typically an fascinating process where robotic systems perform the work with mesmerizing precision.

The entire sequence typically takes 30-60 minutes depending on damage complexity, concluding with verification imaging that confirms the repair has restored the glass’s structural integrity before you ever leave the shop.

The Cost Question: Is AI Repair More Expensive for Me?

The financial implications of AI technology understandably concern cost-conscious consumers, but the reality often contradicts expectations.

While the price of smart windshield replacement might carry a 10-20% premium over basic glass replacement, the cost comparison AI vs manual actually favors AI when considering complete solutions. Many repairs that would require replacement under traditional assessment can be safely repaired with AI guidance, saving consumers $200-$400 per incident while delivering equivalent safety outcomes.

The cost savings calculator becomes even more compelling when considering long-term value. AI-repaired windshields demonstrate significantly lower failure rates over time, meaning you’re less likely to need subsequent repairs for the same damage.

Additionally, proper ADAS calibration performed during AI-assisted replacement ensures your safety systems function correctly, potentially preventing accidents that would far exceed any repair cost difference. When insurers recognize the superior outcomes, they often preferentially recommend AI-equipped shops, sometimes with better coverage terms for consumers.

Your Phone as a Tool: Using AI Apps for Damage Assessment

The democratization of AI technology means you don’t need to visit a shop for initial damage assessment anymore, making mobile auto glass services more effective than ever. Several mobile inspection app platforms now allow consumers to conduct preliminary evaluations using their smartphone cameras.

These apps use simplified computer vision crack detection to analyze damage photos, providing immediate guidance on repair likelihood and urgency. While not replacing professional assessment, they offer valuable peace of mind when damage first occurs.

The mobile app functionality typically includes damage documentation features that create timestamped records of when damage occurred—valuable evidence for insurance claims.

The best apps also incorporate real-time alert systems that notify you if your damage appears to be worsening based on comparison images taken over time. This mobile photo analysis technology represents the first step in a continuum of AI-assisted care that continues through professional repair and final safety verification.

5 Critical AI Questions to Ask Your Auto Glass Shop

Not all shops claiming AI capabilities offer the same level of technology integration. When selecting a provider for your windshield repair, these five questions help identify shops with genuine AI expertise:

- “What specific AI-powered diagnostic equipmentdo you use for damage assessment?” (Look for specific system names rather than vague “we use AI” claims)

- “How do you verify ADAS calibrationafter windshield replacement, and what documentation do you provide?” (Proper calibration should include before-and-after system verification)

- “What’s your process for detecting microscopic flaws and delamination that might not be visible?” (Comprehensive shops use specialized imaging beyond basic visual inspection)

- “Can you show me the calibration certificate and repair verification report?” (Reputable shops provide detailed documentation)

- “How does your AI implementation affect windshield warranties coverage compared to traditional methods?” (AI repairs often come with enhanced warranty protection)

Beyond Repair: The Future of Smart Auto Glass

The auto glass of tomorrow represents a radical departure from today’s “dumb” glass, evolving into an active component of your vehicle’s safety and connectivity systems. The convergence of smart glass technology, IoT integration, and advanced materials science is creating windshields that do far more than just keep wind and weather outside your vehicle.

These developments point toward glass that actively contributes to driving safety, vehicle efficiency, and passenger comfort in ways that seemed like science fiction just a decade ago.

What makes this transition particularly exciting is how seamlessly these technologies integrate with the AI repair systems we’ve discussed. The same computer vision systems that analyze damage today will monitor the health of smart glass tomorrow, while the data fusion technology used in calibration will enable new glass-based features we’re only beginning to imagine.

This creates a virtuous cycle where repair technologies and glass innovations advance together, each pushing the other toward higher standards of performance and reliability.

Smart Windscreens: Enhancing Visibility and Safety

The next generation of automotive glass goes beyond passive protection to actively enhance your driving experience. Smart windscreens incorporate electrochromic technologies that can instantly adjust tint levels to reduce glare, while embedded sensors monitor external conditions like rain, fog, and light levels to optimize visibility.

These systems work in concert with your vehicle’s safety computers, creating an adaptive visual environment that responds to changing driving conditions in real-time.

The safety implications extend to accident prevention through advanced hazard detection capabilities. Future windshields will incorporate transparent display technologies that highlight potential dangers in your path—pedestrians, obstacles, or road hazards—while providing intuitive navigation cues that keep your eyes on the road rather than glancing at screens.

This heads-up display (HUD) evolution represents a fundamental shift from glass as something you look through to glass as an active participant in the driving experience.

Augmented Reality (AR) Displays

The most visible advancement in smart glass technology comes through augmented reality displays that transform your entire windshield into an informational canvas.

Unlike current heads-up displays that project basic data onto a small portion of the glass, AR systems cover the entire visual field with contextual information that appears to float in the driving environment. Navigation arrows seem to point down the actual road, while safety warnings highlight specific vehicles or pedestrians that require your attention.

These augmented reality glass repair systems require incredibly precise calibration to ensure virtual elements align perfectly with the real world—a process that depends heavily on the AI calibration technologies discussed earlier.

The glass itself becomes a sophisticated optical component that must maintain perfect clarity and dimensional stability, making proper repair and replacement even more critical than with conventional windshields. The real-time processing capabilities needed for these systems represent some of the most demanding automotive computing applications currently in development.

Self-Adjusting Tint and Hazard Detection

Imagine a windshield that automatically darkens when the sun emerges from behind clouds, or one that highlights black ice on the road before you can see it with your naked eye.

These capabilities are becoming reality through smart glass nanotechnology that embeds microscopic particles suspended in liquid crystal arrays between glass layers. When electrical current passes through these arrays, they align to control light transmission with precision impossible through traditional tinting methods.

The hazard detection component works through multispectral imaging that sees beyond the visible light spectrum. Sensors embedded in the glass can detect temperature variations that indicate black ice formation, or moisture patterns that suggest hydroplaning risk before you encounter traction loss.

This technology represents a fundamental shift from reactive safety systems (like anti-lock brakes that activate during skids) to proactive systems that help you avoid dangerous situations entirely.

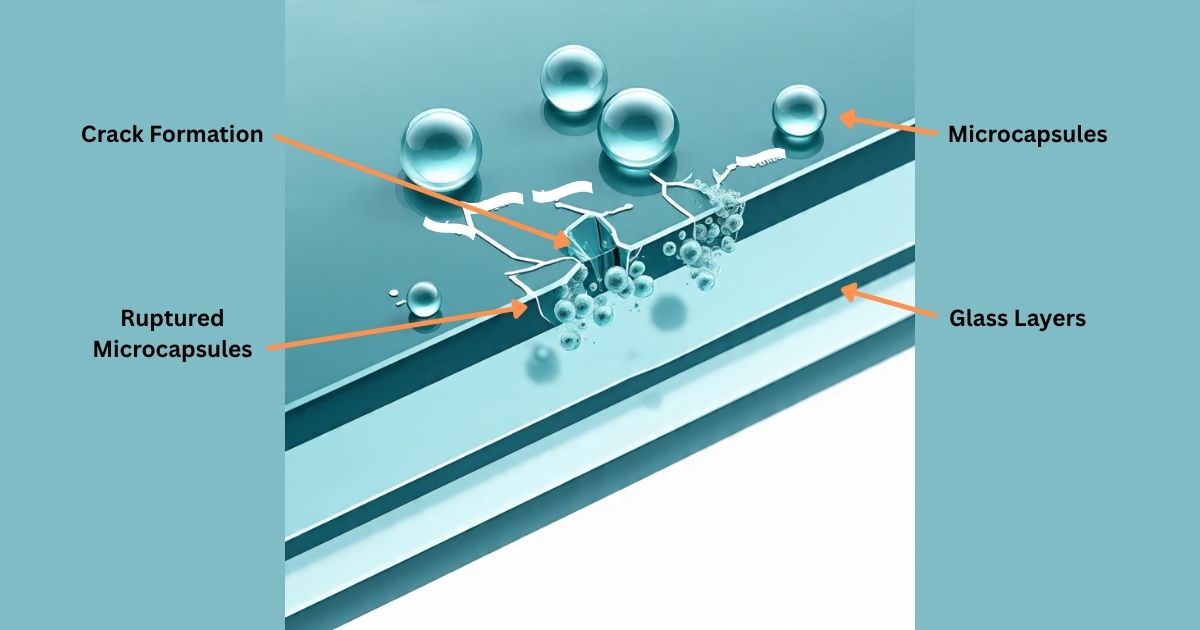

Self-Healing Glass: The Science of Microscopic Repair

The concept of self-healing auto glass might sound like science fiction, but the underlying technology already exists in laboratory settings and is progressing toward commercial viability.

The approach involves embedding microcapsules filled with polymer healing agents between glass layers. When cracks form, these capsules rupture and release their contents into the damage area, where exposure to ultraviolet light catalyzes a hardening process that restores structural integrity.

The science of microscopic repair extends beyond simple crack filling to actual molecular rebonding of the glass structure. Some experimental formulations use polymers containing reversible chemical bonds that can reattach when brought into contact, essentially “healing” the glass at a molecular level when heated slightly by sunlight or applied energy.

While widespread commercial application remains several years away, the progress demonstrates how material science and AI are converging to create maintenance-free glass solutions.

The Connected Windshield: IoT, 5G, and Predictive Maintenance

Your windshield is becoming a sophisticated network node in what engineers call the “connected vehicle ecosystem.” Through IoT sensors in auto glass, future windshields will continuously monitor their own health—detecting stress patterns, temperature variations, and microscopic damage that might eventually require repair.

This predictive maintenance capability means your vehicle could notify you of developing glass issues weeks or months before they become safety concerns or visibility problems.

The 5G connected windshield systems enable real-time data exchange between your vehicle and repair facilities. If sensors detect damage, they can automatically schedule service appointments, order replacement glass if needed, and even verify insurance coverage before you’re aware there’s an issue.

This IoT integration transforms auto glass from a passive component to an active participant in your vehicle’s maintenance ecosystem, potentially eliminating the need for manual inspections while ensuring issues are addressed at the optimal time.

Augmented Reality Displays: Turning Your Windshield into an Informational Hub

The ultimate expression of smart glass technology transforms your entire windshield into what designers call an “informational hub” that seamlessly integrates data with your visual environment.

Unlike current systems that project information onto a small portion of the glass, true augmented reality displays use waveguide technology to make the entire glass surface a display medium. This creates the illusion that navigation cues, safety warnings, and vehicle data actually exist in the driving environment rather than on the glass itself.

The implementation requires incredibly sophisticated sensor fusion between the glass-embedded systems and the vehicle’s other safety computers. The technology must understand exactly what you’re seeing through the glass to position virtual elements correctly—a process that depends on the precise calibration capabilities we discussed earlier.

As these systems mature, they’ll fundamentally change how we interact with our vehicles, making driving both safer and more intuitive through glass that enhances reality rather than simply framing it.

Addressing the Realities: Challenges and the Human Element

While the benefits of AI in auto glass repair are substantial, implementing these technologies presents real challenges that shops must navigate thoughtfully. The cost and hurdles of technology adoption extend beyond financial investment to include workflow disruption, staff retraining, and changing customer expectations.

Successful integration requires balancing technological advancement with practical business considerations, ensuring that AI enhances rather than complicates the repair process for both shops and their customers.

Perhaps the most significant challenge lies in managing the transition from traditional to AI-assisted workflows. Technicians accustomed to relying on their experience and judgment may initially resist systems that sometimes contradict their assessments, even when data supports the AI’s conclusions.

This human element requires careful change management that positions AI as a tool that enhances technician capabilities rather than replaces their expertise—a collaboration between human experience and machine precision that produces outcomes neither could achieve alone.

The Cost and Hurdles of Technology Adoption

The financial barriers to AI adoption represent the most immediate challenge for many shop owners. Beyond the substantial AI system implementation costs, shops face significant training expenses and potential revenue disruption during the transition period.

The hardware compatibility requirements often necessitate additional investments in shop infrastructure, from electrical upgrades to accommodate robotic systems to enhanced computing networks for data-intensive AI applications.

The implementation hurdles extend beyond finances to operational challenges. The system integration protocols can create temporary workflow inefficiencies as staff adapt to new processes, while the technical requirements list may exceed the capabilities of older facilities.

Perhaps most challenging is the knowledge gap that often exists between traditional glass work and computer-assisted repair—bridging this divide requires both equipment investment and significant commitment to staff development through comprehensive training certification programs.

Current AI Limitations: Weather Interference and System Errors

Despite their impressive capabilities, AI systems face very real limitations that technicians must understand and accommodate. Weather interference represents a particular challenge—heavy rain, bright sunlight, or frost on the glass can compromise the imaging systems that AI depends on for accurate assessment. Technicians must learn to recognize when environmental conditions require manual overrides or additional verification steps to ensure assessment accuracy.

System errors represent another limitation, though these typically differ from human error patterns. AI systems might struggle with unusual damage types they haven’t encountered in their training data, or they might misinterpret complex crack patterns that human technicians would recognize through experience—which is why DIY windshield repair remains risky.

These current AI limitations highlight why the technology works best as a collaboration between human expertise and machine precision—each catching errors the other might miss to create a repair process that’s more reliable than either approach alone.

The Evolving Role of the Auto Glass Technician

The integration of AI technologies doesn’t eliminate the need for skilled technicians—it transforms their role from manual artisans to technology managers. The evolving role of the auto glass technician increasingly emphasizes system operation, data interpretation, and quality verification rather than manual dexterity alone.

Technicians become the crucial link between AI recommendations and real-world implementation, providing the contextual understanding that pure automation still lacks.

This transformation creates new skill requirements that extend beyond traditional glass work to include basic software operation, data analysis, and system troubleshooting. The future workforce planning for shops must account for these changing competencies, potentially requiring different hiring profiles and certainly demanding ongoing training investments. Rather than making technicians obsolete, AI elevates their work from repetitive manual tasks to higher-value judgment and verification roles—a change that typically makes the work more engaging while commanding better compensation.

Conclusion

The integration of AI in Auto Glass Repair is far more than an upgrade—it’s a fundamental paradigm shift that redefines your vehicle’s safety and the technology protecting it. The 2025 Technology Revolution ends the guesswork era, replacing subjective assessments with data-driven certainty and manual processes with robotic precision. This isn’t just about faster repairs—it’s about a new safety standard where every repair is verified, every calibration is perfect, and every driver gains absolute confidence in their windshield’s integrity.

Looking ahead, the same AI-powered diagnostics and sensor fusion technologies revolutionizing repairs today are building the foundation for tomorrow’s smart windscreens and self-healing glass. The line between repair and innovation is blurring, leading to a future where your windshield is repaired with microscopic accuracy while actively monitoring its health, enhancing visibility, and serving as an informational hub.

For shop owners, adopting this technology is a strategic imperative to stay competitive and trusted. For drivers, it ensures your vehicle’s most critical safety component receives the precision care it deserves. The future of auto glass is clear, intelligent, and here to stay.

People also ask (FAQs)

Q: How accurate is AI in detecting windshield damage compared to a technician?

A: AI detection achieves 99.8% accuracy, significantly higher than the 85-90% typical of manual inspection.

Q: Can AI handle all types of windshield damage?

A: AI excels with most damage but has limitations with extreme weather interference or certain complex, deep cracks.

Q: Can AI tell if my windshield needs replacement or just repair?

A: Yes, AI analyzes depth, location, and size to provide a data-driven repair-or-replace recommendation.

Q: What is the most common AI tool used in repair shops today?

A: Computer vision-based diagnostic scanners that use machine learning to assess damage are the most common.

Q: As a car owner, will I pay more for a repair done with AI?

A: Not necessarily; while the service may have a premium, AI often enables cheaper repairs by saving costlier replacements.

Q: What’s the cost difference between AI and traditional repair?

A: AI can be 10-20% more expensive for replacement but often saves money by making repairs possible where replacements were once the only option.

Q: How does AI work with insurance claims?

A: AI automates claims with verifiable damage reports and photos, speeding up approvals and reducing disputes with adjusters.

Q: Can AI tools work on any car, especially older models?

A: Yes, but they are most effective on modern vehicles with standardized glass and sensor systems.

Q: What training do technicians need for AI systems?

A: Technicians need certification programs focused on software operation, data interpretation, and system troubleshooting.

Q: Do I always need ADAS calibration after a windshield replacement?

A: Yes, on modern vehicles with ADAS, calibration is mandatory to ensure safety systems like automatic braking function correctly.

Q: Who can perform ADAS calibration—a dealer or an independent shop?

A: Both can perform it, provided they have the proper AI calibration tools and certified technicians.

Q: How much does ADAS recalibration cost, and who pays for it?

A: ADAS recalibration costs range from $150 to over $1,000, with most vehicles falling in the $300-$600 range, and is typically covered by insurance when part of a windshield replacement claim.

Q: Are mobile windshield replacements safe for cars with ADAS?

A: Yes, if the mobile service uses certified AI calibration tools on-site; otherwise, a shop visit is necessary for safety.